Achieving Consistent Results

In the printing and photo industry, consistency is key. Whether it's ensuring that a printed image matches the digital file or maintaining color accuracy across different production runs, achieving consistent results is crucial for success. And when it comes to measuring and analyzing color, spectrophotometers play a pivotal role.

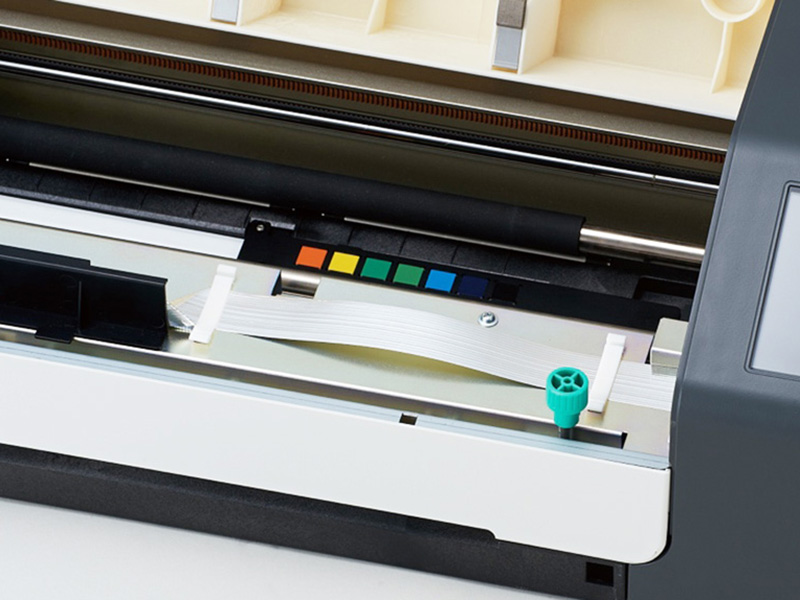

A spectrophotometer is a device used to measure the intensity of light at different wavelengths. It can be used to quantify the color and appearance of various materials, making it an invaluable tool for industries that rely on accurate color reproduction, such as printing and photography.

Consistency in spectrophotometer results refers to the ability of the device to provide the same measurements when analyzing the same sample under identical conditions. In other words, it means that if you were to measure the color of an object multiple times using the same spectrophotometer, you would expect to obtain the same results each time.

Consistency is important because it ensures that color specifications are met, allowing for predictable and reliable color reproduction. It also helps in quality control processes, where consistency in color measurement is necessary to identify any deviations or defects in the final product.

Maintaining Result Reliability

One of the challenges in maintaining result reliability with spectrophotometers is the variation in measurements between different instruments. Different instruments can have disparities in their readings, even when measuring the same sample.

These variations can be attributed to several factors, including differences in calibration, age of the instrument, and manufacturing tolerances. The key to mitigating these variations is through regular calibration and instrument maintenance.

Calibration is the process of adjusting the spectrophotometer to ensure its accuracy and consistency. By comparing the device's readings to a known standard, any discrepancies can be identified and corrected. Calibration should be performed regularly, ideally following a defined schedule or whenever the instrument shows signs of drift or inconsistencies. For a better understanding, please check our post about What is the daily (white tile) calibration?

Maintenance also plays a crucial role in maintaining result reliability. Keeping the spectrophotometer clean and free from dust or debris can prevent any interference with its measurements. Regular inspections and servicing can identify any potential mechanical issues that may affect the accuracy of the device. Check our post about Why is a periodic inspection and calibration for a spectrophotometer needed? for more information.

Spectrophotometer Data Consistency

When it comes to comparing spectrophotometer data from different instruments, it is important to consider the agreement or compatibility between them. While it is expected that there will be some level of variation between different devices, it is essential to understand the extent of this variation to ensure reliable and consistent results.

Some spectrophotometers have better agreement or correlation with each other, while others may exhibit larger discrepancies. This agreement can be quantified through statistical analysis, such as calculating the correlation coefficient between the measurements obtained from different instruments.

A regular scenario is the failure of quality control which can be attributed to the differences in measurements between two instruments (A and B). If the agreement between these instruments is poor, it can lead to false positives or negatives in quality control processes, resulting in unnecessary rejections or acceptance of products that do not meet specifications.

To address this issue, it is crucial to evaluate the agreement between spectrophotometers used in different stages of the production process. Validating the compatibility and consistency of these instruments can help minimize the risk of false results and improve the overall quality control system.

Furthermore, it is recommended to establish a standard operating procedure (SOP) for spectrophotometer usage, including guidelines for instrument selection, calibration, and data interpretation. This SOP should be followed consistently across the organization to ensure uniformity and reliability in color measurements.

Additionally, investing in spectrophotometers with better agreement or compatibility can help mitigate the risk of inconsistent results. Researching and selecting instruments that have been proven to provide reliable and consistent measurements can significantly contribute to improving overall color accuracy and quality control.

In conclusion

The importance of consistency in spectrophotometer results cannot be overstated. It is essential for achieving accurate color reproduction, maintaining quality control, and meeting customer expectations. By understanding the factors that influence consistency, implementing regular calibration and maintenance practices, and evaluating the agreement between different spectrophotometers, professionals in the printing and photo industry can strive for excellence in color management.

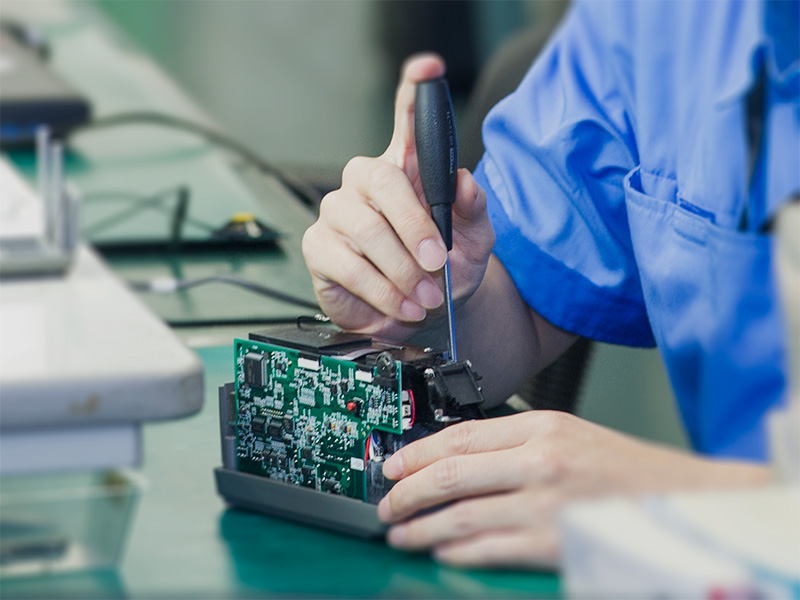

An inspection followed by the necessary adjustments will be performed in our service center by a certified technician. We recommend to perform an inspection & calibration every year.

Follow the service plan and make savings in the long run by avoiding unexpected and expensive repairs, in addition benefit from a discount on the regular calibration service

Your device is inoperative/broken and need to be inspected and repaired in our service center. This is also the right option to fill a warranty claim